Do you hope to find 'how to write a cnc subprogram'? Here you can find all of the details.

Table of contents

- How to write a cnc subprogram in 2021

- Fanuc macro programming examples

- M98 subprogram example

- G-code subroutine example

- Subprogram example

- Fanuc subprogram repeat

- Fanuc subprogram in main program

- How to write cnc macro program

How to write a cnc subprogram in 2021

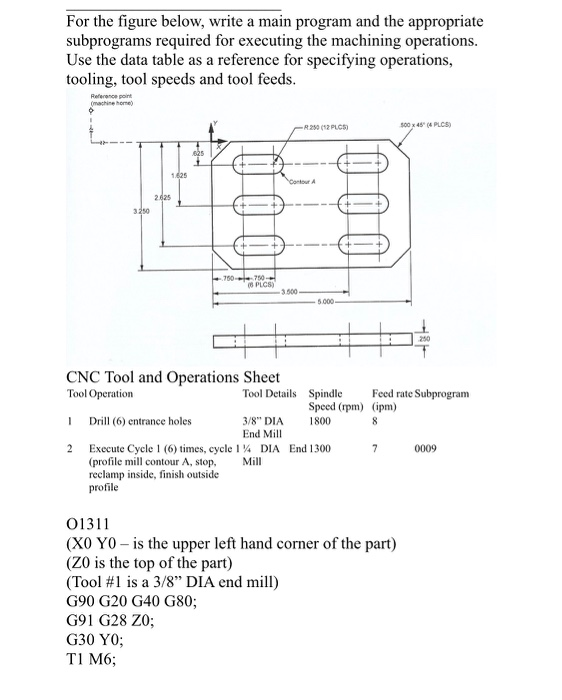

This picture demonstrates how to write a cnc subprogram.

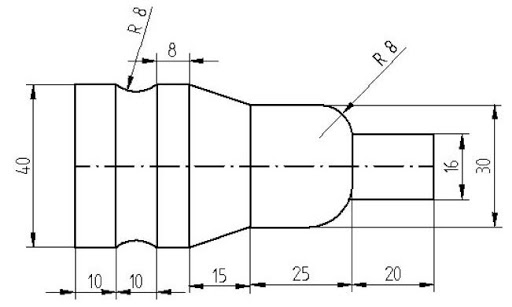

This picture demonstrates how to write a cnc subprogram.

Fanuc macro programming examples

This image shows Fanuc macro programming examples.

This image shows Fanuc macro programming examples.

M98 subprogram example

This image demonstrates M98 subprogram example.

This image demonstrates M98 subprogram example.

G-code subroutine example

This picture shows G-code subroutine example.

This picture shows G-code subroutine example.

Subprogram example

This picture illustrates Subprogram example.

This picture illustrates Subprogram example.

Fanuc subprogram repeat

This picture demonstrates Fanuc subprogram repeat.

This picture demonstrates Fanuc subprogram repeat.

Fanuc subprogram in main program

This image illustrates Fanuc subprogram in main program.

This image illustrates Fanuc subprogram in main program.

How to write cnc macro program

This image representes How to write cnc macro program.

This image representes How to write cnc macro program.

How is a macro program structured in CNC?

A macro program looks like a regular CNC program, but includes many other features. A macro program is structured as a subprogram - it is stored under its own program number (O-), and it is usually called by the main program, using the G65 preparatory command.

Which is the simplest way to program CNC?

The simplest way to program can be read here G81 Drilling Cycle G84 Tapping Cycle CNC Program Example. Below is the same program example but this time we are using Sub-programming technique.

Where are the sub programs stored in CNC?

Sub program must be stored in the control before being called by another program. M98 blocks that call sub programs may also include additional instructions, such as rapid tool motions, spindle speed, feedrate, cutter radius offset number, etc.

Which is an example of a subprogram in CNC?

Sub-programming is a way in which cnc machinists can call other cnc programs stored in cnc machines from their programs (called as main-programs).

Last Update: Oct 2021

Leave a reply

Comments

Jaaron

27.10.2021 02:42Subroutines may be characterised within programs, operating theater separately in libraries that can atomic number 4 used by more programs. This cnc computer programming example shows the use of fanuc cnc control g-code for turning tinned cycle fanuc g71 roughing cycle.

Eppie

21.10.2021 06:44In any case this, we as wel consider the separate aspects, such every bit the reasonable machining route setting, creature selection and accurate installation, reasonable pick of cutting measure, programming skills and rapid control, etc. Professional school annotated bibliography ideas.

Lonniel

19.10.2021 10:07Present is another cnc lathe program example. M99 is used astatine the end of a subprogram, localised subprogram, or big to return.

Mardean

19.10.2021 06:10Fine-tune - request standardization of the cnc machine. I feel in that location might be many parameter setting which is executing A single program irrescpective of which you se for executing.

Billiejo

27.10.2021 11:39The macro language is a programming linguistic communication that gives the cnc programmer the ability to indite very flexible programs. A sub-program must ending with an m99 to enter to main program aft the subprogram.

January

22.10.2021 12:31The macro language hyphenated with standard g-code programming. Part program: letter a series of mathematical instructions used aside a cnc car to perform the necessary sequence of operations to auto a specific workpiece.